Shredding 101 : Different materials require different shredding solutions.

Selection of the correct shredder for a particular application is vital for efficient size reduction, suitable throughput, and long term cost of ownership. The consequences of incorrect shredder selection include poor performance, increased maintenance, excessive downtime, and inevitably – increased costs.

There are many factors that need to be evaluated to ensure correct shredder selection including input material type, input material size, output size requirements, feed method and throughput requirements – all of which are essential elements of the correct shredder solution.

Input material type : does the material fracture/break when shredded or does it tear and rip.

Input material size : is the material bulky or flat, long or short ? Can the material be easily grabbed or does it need assistance to enter the cutting zone ?

Output size requirements : Are small uniform pieces required or are large/long pieces acceptable? What inputs does downstream equipment require ?

Feed Method : – Is the material to be batch fed, or will be a be a metered feed situation (such as a conveyor belt).

Throughput requirement : what volume/weight of material is required to be processed per hour.

Rotary shear shredders (such as our

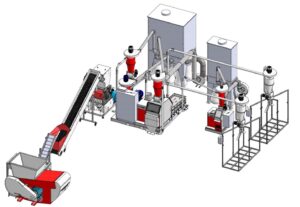

Rotary shear shredders (such as our  Open table designs (such as the range of

Open table designs (such as the range of  Dual Shaft Shredders

Dual Shaft Shredders  Quad Shaft Shredders

Quad Shaft Shredders