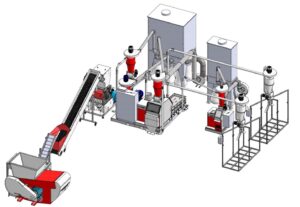

M&J Fine Shredders

M&J are the shredding experts.

M&J specialises in the design and manufacture of shredding equipment that effectively and reliably reduces the size of waste materials of all kinds. They are one of the world’s leading suppliers of shredders for the waste handling industry. Their customers include companies that work with incineration, hazardous waste, waste-to-energy conversion, recycling, landfills, cement production and composting.

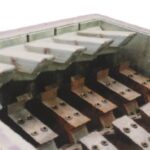

Shaft & Knives

Shaft & Knives Hydraulic Drive

Hydraulic Drive Screen

Screen