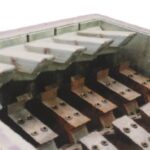

So – Why Are We So Proud Of Our Cutters?

More than 40 years of experience in manufacturing cutters for the most demanding applications is represented in the range of high strength cutters that we supply with our new machines and as aftermarket replacements for the wide range of Brentwood Shredders in the market today.

The selection of cutter materials and the manufacturing methods used to build our cutters are key to the superior core strength and superior surface hardness of our cutters. Brentwood cutters are manufactured from material far superior to any other material currently on the market today and are manufactured to exact tolerances to suit our shredders.

When you purchase Brentwood cutters you are investing in experience.