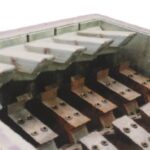

Brentwood manufacture heavy duty industrial shredders, conveying and sorting equipment, and customised engineering solutions.

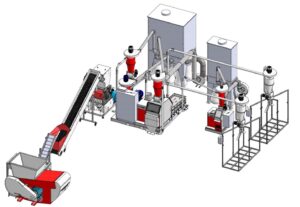

From full turn-key plants to individual one-off machines, Brentwood can supply standard equipment from our extensive range or we will engineer a complete solution to help you meet your business goals.

Brentwood is one of Australia’s leading manufacturers and supplier of recycling and waste processing machinery. With 47 years of experience, Brentwood Recycling Systems has the expertise, experience and capacity you need to create effective, commercial solutions.

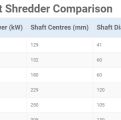

We are the only Australian manufacturer of Heavy Duty Industrial Shredders and coupled with our design and engineering experience, we can incorporate our range of Industrial Shredding equipment into your plant or develop a new solution using our wide range of core technologies.